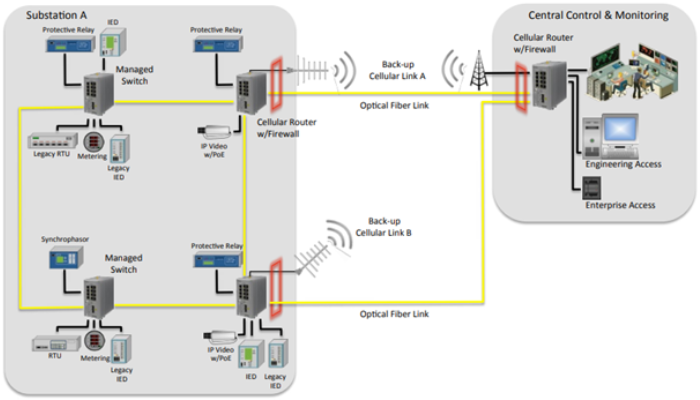

Power Distribution Network and Power Plants

The PM-22XX industrial routers are widely used in the power industry. These routers provide efficient and intelligent communication and management capabilities for the entire power generation and distribution system. Below are some of their key applications in this industry:

Remote Monitoring and Control

The PM-22XX industrial routers enable remote monitoring and control of power substations. By connecting to the 4G network, users can remotely monitor the operational status of equipment such as meters, power load, and other key parameters, and control the switching status and power consumption of equipment in real-time. This capability can make the power distribution network smarter and more efficient.

Data Collection and Analysis

The PM-22XX industrial router can collect and transmit data from equipment in power substations. This data is gathered in a central database for analysis and processing. Through real-time monitoring and analysis, equipment failures can be predicted in advance, reducing downtime and facilitating the optimization of the power distribution system’s performance efficiency.

Energy Management

The PM-22XX industrial router integrates with energy monitoring devices to collect and transmit energy consumption data. This system is capable of energy monitoring, energy measurement, and implementing energy-saving measures. Through this monitoring and optimization, energy efficiency is increased, and energy waste is reduced.

Security Protection

The PM-22XX industrial router provides network security mechanisms to ensure data and communication security. It supports encrypted VPN communications, firewalls, and access control to prevent unauthorized access and data leakage.

Fault Detection and Maintenance

Using the PM-22XX industrial router, faults in the distribution network can be detected, and maintenance of the distribution system equipment can be carried out in a shorter time. Through remote access and monitoring, equipment faults are identified promptly, and maintenance actions are taken, resulting in reduced downtime and maintenance costs.

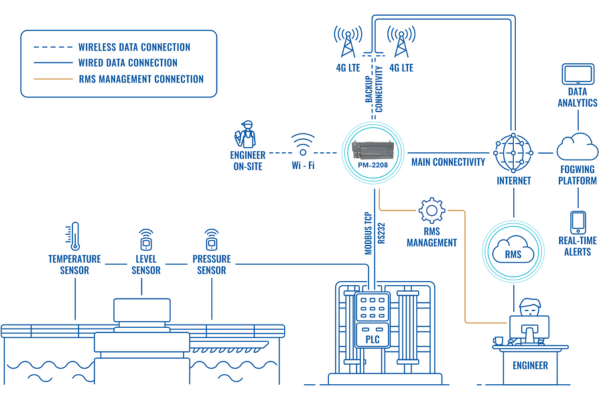

Water Transmission Network and Wastewater Treatment

The role of the LTE 4G cellular modem in wastewater treatment application scenarios is as follows:

- Online Monitoring

The PM-22XX industrial router can perform real-time monitoring of wastewater treatment equipment, including water quality, water quantity, and equipment operational status. Data is transmitted to the server via the internet, enabling remote monitoring and management. - Remote Control

The PM-22XX industrial router enables remote control of wastewater treatment equipment, including turning devices on and off, adjusting parameters, upgrading the operating system, and more. Instructions are transmitted to the equipment via the internet. - Fault Detection

The PM-22XX industrial router can detect faults in wastewater treatment equipment, including locating and diagnosing issues. Error information is transmitted to the server via the internet, enabling remote maintenance and equipment management. - Data Analysis

The PM-22XX industrial router transmits collected wastewater treatment data to the server for analysis and extraction, allowing timely identification of issues and optimization of equipment performance. - Energy Saving and Emission Reduction

The PM-22XX industrial router can facilitate energy savings and reduce pollutant emissions in wastewater treatment equipment. It reduces energy consumption and emissions through remote control and optimization of equipment performance, contributing to environmental protection and sustainable development.

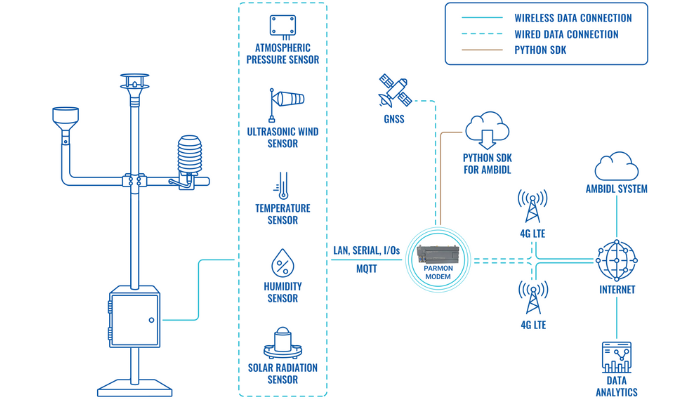

Meteorology and Weather Monitoring

Remote weather monitoring, as one of the fundamental branches of meteorology, faces various challenges. Monitoring stations are often located in remote and harsh environments, making manual data collection and transmission extremely difficult. Additionally, weather monitoring requires real-time access to data, as any delay may impact the accuracy of weather change analysis. The PM-22XX industrial router, specifically designed for industrial environments, demonstrates its technological advantages in remote weather monitoring:

1. Stability and Reliability

Remote weather monitoring, as one of the fundamental branches of meteorology, faces various challenges. Monitoring stations are often located in remote and harsh environments, making manual data collection and transmission extremely difficult. Additionally, weather monitoring requires real-time access to data, as any delay may impact the accuracy of weather change analysis. The PM-22XX industrial router, specifically designed for industrial environments, demonstrates its technological advantages in remote weather monitoring:

2. High-Speed Data Transmission

High-speed data transmission capabilities over 4G networks enable real-time and accurate transmission of remote weather monitoring data to data centers, providing strong support for weather analysis.

3. Remote Control and Maintenance

Through 4G networks, users can remotely access and control weather monitoring equipment. This allows for remote troubleshooting, configuration, and upgrades, significantly reducing maintenance costs and improving operational efficiency.

4. Security

The PM-22XX industrial router supports various security protocols and encryption technologies, ensuring the security of data transmission and preventing data leakage and tampering.

Industrial Production Line Monitoring

The PM-22XX industrial router is widely used in monitoring industrial production lines and other environments. The main difference between these routers and ordinary home routers lies in their greater durability, stability, and industrial-grade connections. These routers can adapt to complex industrial environments such as high temperatures, high humidity, and noisy electromagnetic conditions. At the same time, they feature fast routing, network isolation, encrypted data transmission, and industrial connections such as RS485 and RS232. These routers have numerous applications in industrial production line monitoring, including

Data Transmission and Monitoring

Monitoring industrial production lines requires multiple connections for data transmission. The PM-22XX industrial router can provide a stable and high-speed data transmission channel for real-time monitoring and remote access to production data.

Network Isolation and Security

The PM-22XX industrial router enables network isolation, separating the production line network from the company’s internal network to ensure the security of production data. It also provides security features such as firewalls, virtual private networks (VPNs), and data encryption to protect the production line monitoring system from network attacks and data leaks.

Remote Maintenance and Management

The PM-22XX industrial router enables remote access and management. Engineers can perform remote maintenance, troubleshooting, and software upgrades for the monitoring system, improving the system’s reliability and operational efficiency.

Implementation of Industrial Internet of Things (IIoT)

The PM-22XX industrial router is a key component of the Industrial Internet of Things (IIoT). It can connect various devices and sensors to the production line network, facilitating real-time data collection, device-to-device communication, and data analysis. This connectivity and analysis help optimize production lines and enable smart manufacturing.

Urban and Suburban Traffic Management

Intelligent traffic guidance systems provide drivers with optimal routes based on real-time traffic information. Industrial routers play a crucial role in these systems. By accessing traffic flow, speed, accidents, and other data, the PM-22XX industrial router transmits this information to intelligent traffic guidance systems and offers precise driving suggestions to drivers. This not only reduces travel time and fuel consumption but also improves the overall efficiency of road traffic.

As traffic management becomes smarter, issues related to data security and privacy protection become more prominent. The PM-22XX industrial router, with its support for multiple communication protocols and data encryption mechanisms, ensures the security and reliability of traffic data transmission. Additionally, its network isolation and traffic control functions prevent network attacks and data breaches, providing comprehensive security for intelligent traffic management systems.

Oil and Gas Industry

Oil and gas wells are located in harsh industrial environments, and their measurement equipment—such as gas meters, SCADA systems, temperature sensors, pressure sensors, motor flow sensors, voltage sensors, pump unit load sensors, and unmanned devices—are geographically dispersed. Relevant personnel must monitor the operational status of all machinery in real time to promptly identify any faults, reduce downtime, and lower maintenance costs.

The PM-22XX industrial router connects all sensor devices in the oil and gas industry to a secure network, helping companies collect sensor data and transmit it to the data management center. Engineers can monitor and manage all machinery in real time to reduce security risks in oil and gas fields and improve operational efficiency.

Additionally, in gas transmission networks, high-pressure station meters can be read online using PM-22XX industrial modems, and control commands for turning pumps on or off can be sent through them.

Advantages

Easy deployment, avoiding the limitations of wired network infrastructure.

Strong environmental compatibility and stable performance in harsh conditions

Compatibility with industrial equipment via RS232/485 serial and Ethernet interfaces

Automatic recovery to ensure 24/7 continuous operation.

Cost-effective for deployment and relocation.

Supports remote monitoring, estartin upgradg, configuratiron,es, and more.

Industrial GreenHouses

Plants grown in greenhouses typically have strict requirements for their growth environment, including temperature, humidity, carbon dioxide concentration, and other indicators that must be maintained within a stable range. In non-industrial greenhouses, temperature, soil moisture, light intensity, and other parameters are manually observed and recorded, with monitoring primarily carried out by personnel. As the scale of greenhouses increases, manual management becomes more challenging.

With the rapid development of IoT technology and agricultural automation in recent years, an automated monitoring system for smart greenhouses based on IoT technology is now widely available. This system can adjust greenhouse temperature, irrigation timing, and other parameters in real time based on environmental data. With high-precision control and stable performance, it reduces labor costs and makes IoT-based smart greenhouses the future of agriculture.

To develop high-efficiency agricultural greenhouses with optimal security, a smart IoT-based system has been proposed. This system includes online collection of environmental parameters, wireless data transmission, information processing, and automatic control. Through the PM-22XX industrial router, farmers can monitor ecological information in real time, receive abnormal alerts, and adjust control equipment based on environmental monitoring results.

Rail Road Monitoring

In the transportation sector, PM-22XX industrial routers connect to vehicles (buses, trains, trucks, cars) to assist with fleet management, passenger information systems, and security, while collecting critical data for system analysis.

In rail transportation, in addition to providing internet access to passengers, POS payment devices can be connected to PM-22XX routers, and all industrial measurement systems in the carriages can be monitored online from a central station.

Large mining machinery can also utilize the PM-22XX industrial router to connect all machine sensors to a secure network. In addition to machinery, all equipment in mines can be monitored online and securely using PM-22XX industrial routers.